High Quality biax power scraper, Sales biax scraper, big scraper in China

In the realm of precision machining and surface finishing, the choice of tools can make all the difference. This comprehensive guide delves into the world of Biax scrapers, with a focus on the dynamic capabilities of the Biax Power Scraper, the versatile Biax Scraper, and the robust Big Scraper. Join us on a journey exploring the mastery, precision, and power encapsulated in these important tools that play a pivotal role in achieving unparalleled surface quality.

The Powerhouse - Biax Power Scraper

The Biax Power Scraper stands as a powerhouse in the field of machining, boasting dynamic capabilities that set it apart. This electrically powered scraper delivers consistent and controlled strokes, ensuring greatmaterial removal and surface finish. The ergonomic design and adjustable settings of the Biax Power Scraper make it an importanttool for tasks requiring precision and efficiency.

With its robust motor and innovative features, the Biax Power Scraper excels in handling large surfaces and challenging materials. Its ability to adapt to varying work conditions, coupled with the precision it offers, makes it a favorite among professionals in industries where surface finish is non-negotiable. As we navigate the capabilities of the Biax Power Scraper, its role in elevating machining precision becomes increasingly evident.

Versatility Redefined - The Biax Scraper

For tasks that demand versatility and manual control, the Biax Scraper takes center stage. This hand-operated tool provides machinists with the flexibility to achieve intricate finishes and contours. The Biax Scraper's finely crafted blades and ergonomic grip make it an ideal choice for craftsmen seeking precision without sacrificing the tactile connection to their work.

The Biax Scraper's adaptability shines in tasks ranging from fine detail work to broader surface finishing. Machinists appreciate the tactile feedback and control that this manual tool offers, allowing them to finesse their work with the nuance that automation may lack. As we explore the versatility redefined by the Biax Scraper, its significance in the hands of skilled craftsmen becomes increasingly apparent.

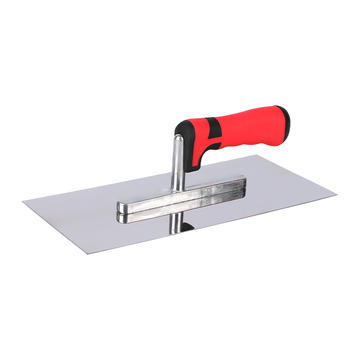

Robust and Reliable - The Big Scraper

When confronted with heavy-duty tasks and challenging materials, the Big Scraper emerges as the go-to solution. This large and robust scraper is designed to tackle demanding surfaces, offering machinists the brawn needed for substantial material removal. The Big Scraper's oversized blades and sturdy construction make it an importanttool in environments where strength and reliability are important.

Whether dealing with thick layers of material or intricate surfaces on a larger scale, the Big Scraper rises to the occasion. Its rugged design and powerful strokes make it the tool of choice for machinists facing heavy-duty machining challenges. The Big Scraper proves that size does matter when it comes to handling substantial tasks with precision and efficiency.

Conclusion:

In the dynamic world of machining and surface finishing, Biax scrapers showcase a spectrum of capabilities, from the precision and power of the Biax Power Scraper to the versatility redefined by the Biax Scraper and the robust reliability of the Big Scraper. Each of these tools caters to specific needs and challenges, offering machinists the means to achieve surface quality with finesse and efficiency.

This comprehensive guide has explored the mastery encapsulated in Biax scrapers, highlighting the dynamic capabilities of the Biax Power Scraper, the versatile nature of the Biax Scraper, and the robust reliability of the Big Scraper. As machinists master the use of these important tools, they contribute not only to the precision of their work but also to the efficiency and effectiveness inherent in the machining process.

English

English Español

Español Deutsch

Deutsch