When people discuss construction tools, items like hammers, drills, or levels often come to mind first. However, for anyone involved in masonry, the Bricklaying Trowel plays a significant and often underestimated role in daily work. This simple, handheld tool directly affects the quality, speed, and comfort of bricklaying tasks. Understanding why your Bricklaying Trowel matters more than you might expect can improve both the outcome of your projects and your overall working experience.

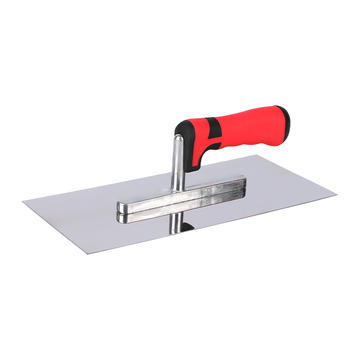

A Bricklaying Trowel is not just a flat piece of metal attached to a handle. Its size, shape, material, and weight all influence how it performs on different types of jobs. While some might think any trowel will get the job done, choosing the right Trowel for your specific needs can make noticeable differences. Factors like blade flexibility, handle grip, and balance help determine how effectively you can spread mortar, shape joints, and position bricks.

One of the main reasons the Bricklaying Trowel is so important lies in its direct interaction with mortar. A reliable Trowel ensures even mortar application, which affects both the strength and appearance of a finished wall. Uneven mortar layers can result in structural weaknesses or visible imperfections. By selecting a trowel suited to your project’s size and mortar type, you can achieve cleaner, stronger brickwork.

Comfort during long work hours is another factor often overlooked. Since the Bricklaying Trowel is used continuously throughout a masonry job, its handle design and overall weight play a role in reducing hand and wrist fatigue. A trowel with a well-shaped handle and balanced weight distribution allows for smoother movements and consistent pressure, which can improve both work speed and precision.

The type of Bricklaying Trowel you choose should also match the scale of the job. Larger blades are typically used for bigger bricks or blocks, while smaller blades suit detailed or decorative work. Using the wrong size Trowel can slow down progress or cause excessive strain. Professional bricklayers often keep several types on hand for different tasks, switching between them depending on what the job requires.

Durability is another essential quality to consider. A good Bricklaying Trowel should maintain its shape and sharpness after repeated use. Tools made from hardened steel or stainless steel offer better resistance to wear and rust. Investing in a reliable Trowel means fewer replacements and better long-term performance.

Beyond physical features, personal preference plays a role, too. Some bricklayers favor a Bricklaying Trowel with a wooden handle for its traditional feel, while others opt for rubber-coated or plastic handles for improved grip in wet or muddy conditions. The angle between the blade and handle, known as the ‘lift,’ also affects comfort and technique. A steeper lift suits certain laying styles, while a shallower one works better for others.

Even for those new to masonry, recognizing how different Bricklaying Trowel designs affect their work can help develop better habits from the beginning. Newcomers who experiment with various trowel types and techniques quickly learn how much the tool influences their speed and the quality of their finished joints.

Another important aspect is maintenance. A well-maintained Bricklaying Trowel will always perform better than a neglected one. Regular cleaning after each job prevents mortar buildup, which can affect the blade’s weight and sharpness. Occasional oiling of metal parts and careful storage can extend the tool’s lifespan and keep it in reliable working condition.

Construction projects often require adaptability, and a Bricklaying Trowel can be surprisingly versatile. Beyond laying bricks, it can be used to scrape, chip, or even measure mortar thickness. This multipurpose use adds value to the tool, making it a practical addition to any builder’s collection.

For contractors managing teams, providing high-quality Bricklaying Trowel options ensures that workers can perform consistently and safely. It’s a small investment that contributes to better project outcomes and worker satisfaction. Keeping a range of blade sizes and handle styles on hand accommodates different preferences and work demands.

English

English Español

Español Deutsch

Deutsch